Specialised cleaning for Food Manufacturing Facilities

We deliver commercial cleaning services specifically designed for food processing facilities, ensuring compliance with stringent industry standards while maintaining operational efficiency.

5+

Food Manufacturing Clients

6+ Years

Industry Experience

100%

Compliance Rate

HACCP Certified Cleaning Services

Our HACCP certification demonstrates our commitment to maintaining the highest standards in food safety through our specialised cleaning and sanitation services.

Why HACCP Certification Matters

HACCP (Hazard Analysis Critical Control Point) is an internationally recognised system for reducing the risk of safety hazards in food. For your business, working with us, a HACCP-certified cleaning service provider, means:

Hazard Prevention

HACCP systematically identifies and controls food safety hazards before they threaten your products

Regulatory Compliance

Our HACCP certification ensures your facility meets stringent international food safety standards

Consumer Confidence

Demonstrate your commitment to producing safe food products that consumers can trust

We understand your unique requirements

Industry-Specific Solutions

Our professional cleaning teams are trained to meet the unique requirements of various food production environments.

Meat Processing

Navigating High-Risk Contamination Zones

Meat processing facilities have zero tolerance for error. The inherent risk from pathogens like Salmonella and E. coli, combined with heavy build-up of fats and proteins in abattoirs, boning rooms, and on equipment, creates a constant compliance challenge. Effective sanitation must address both microbial threats and cross-contamination between raw and finished areas.

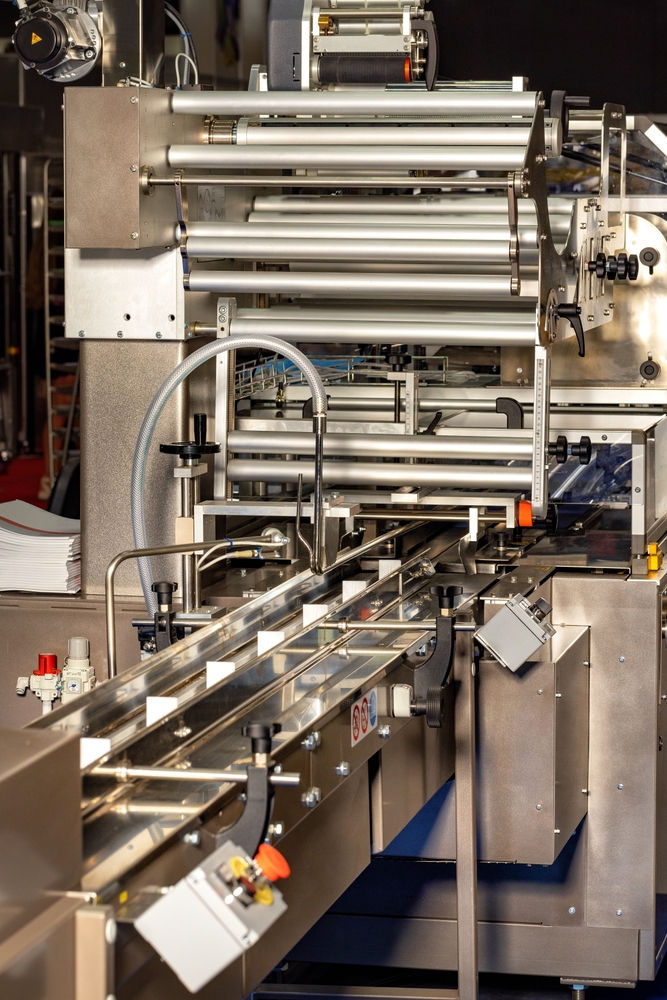

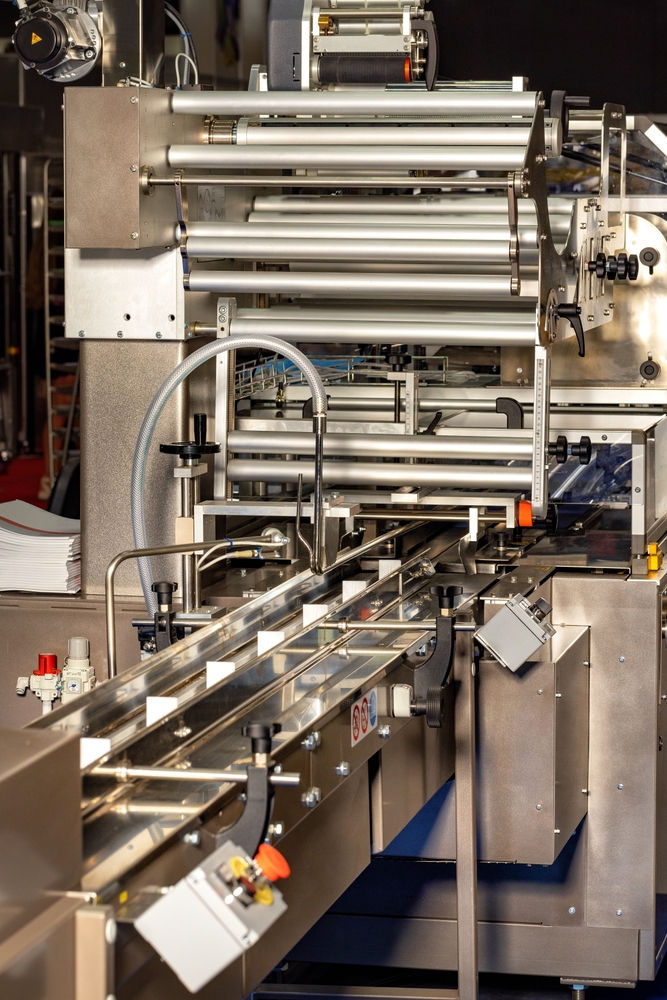

Food Manufacturing

Comprehensive Sanitation for Diverse Production Lines

From mixing vats to ovens, conveyors, and packaging machinery, your facility is a complex ecosystem. Each type of food soil—be it sugars, oils, starches, or powders—requires a specific sanitation protocol. Managing these diverse requirements while maintaining production schedules is a significant operational challenge.

Brewery

Preserving Flavour and Brewing Integrity

A brewery's reputation rests on the quality and consistency of its product. The primary challenge is the complete elimination of wild yeast, mould, and bacteria from fermentation vessels, lines, and tanks. Even microscopic residue can introduce off-flavours, spoil entire batches, and compromise the unique character you've worked hard to create.

Dairy

Combating Spoilage and Biofilm Risks

Dairy products are exceptionally sensitive to spoilage. The critical challenge is preventing invisible biofilm growth and completely removing stubborn milkstone deposits within processing lines, pasteurisation equipment, and storage tanks. This requires a technical approach like dry cleaning that goes far beyond surface-level cleaning to ensure product safety and shelf life.

Packing Plants

Maintaining the Final Line of Defence

As the last touchpoint before your product reaches the consumer, the packing environment is your final quality gate. The challenge is meticulously controlling dust, debris, and potential allergens on conveyor systems, packaging machinery, and environmental surfaces. This final sanitation step is crucial to prevent last-minute contamination and protect the integrity of your sealed product.

Specialised Cleaning Solution for Food Manufacturers

Our comprehensive cleaning solution is specifically designed to address the unique challenges faced by food manufacturing facilities.

Food Safety Compliance

Our cleaning protocols ensure compliance with HACCP food safety standards.

Flexible Scheduling

We work around your production schedule to minimise disruption to your operations.

Specialised Equipment

Purpose-built cleaning equipment designed specifically for food manufacturing environments.

Trained Professionals

Our staff are trained in food safety protocols and manufacturing-specific cleaning techniques.

Cross-Contamination Prevention

Specialised protocols to prevent allergen and pathogen cross-contamination between zones.

Microbial Testing

Optional microbial testing services to verify cleanliness and compliance with standards.

Ready to Enhance Your Facility's Cleanliness?

Our team of experts is ready to provide a customised cleaning solution that meets your specific needs and regulatory requirements.

Schedule a Consultation

“With Emera, our audit process went from a source of stress to a demonstration of our commitment to quality. Their team understands the strict hygiene and compliance requirements in food manufacturing, and they’ve consistently delivered high standards across our site.”

Regulatory Compliance Assurance

Pass Every Audit with Confidence.

Navigating the complexities of HACCP and food safety regulations is a constant pressure. A single compliance failure can lead to shutdowns, fines, and lasting brand damage. Stop reacting to audit risks and start proactively ensuring compliance.

Emera provides peace of mind with HACCP-certified cleaning protocols and meticulous documentation. We guarantee your facility not only meets but exceeds the required standards, making you audit-ready, always.

- HACCP Certification & Expertise.

- Our teams are trained and certified, ensuring every procedure aligns with the highest food safety standards.

- Comprehensive Audit Trails.

- Receive detailed reports and documented cleaning procedures, providing a clear audit trail for regulators.

- Avoid Costly Violations.

- Our proactive approach dramatically reduces your risk of non-compliance penalties and operational interruptions.

Operational Efficiency

Maximise Uptime, Not Downtime

Every minute your production line is stopped for cleaning is a minute of lost revenue. In-house teams often lack the specialised equipment, know-how, and processes to work quickly, forcing you to choose between thorough cleaning and meeting production targets.

Emera integrates seamlessly into your workflow. Our experienced teams use specialised equipment and proven methods to complete cleans faster and more effectively, all scheduled around your production runs to keep your facility operational and profitable.

Flexible Scheduling

We work overnight, on weekends, or between shifts to ensure zero disruption to your core operations.

Faster Turnaround

Our trained specialists and efficient processes mean less time cleaning and more time producing.

Specialised Equipment

We invest in the best equipment so you don't have to, delivering a deeper clean in less time.

HACCP-Compliant Cleaning

Our cleaning protocols are designed to meet the strictest HACCP standards, ensuring your facility is always compliant.

Production Impact Analysis

Before Emera:

4-6 hoursAverage cleaning downtime per shift

With Emera:

1-2 hours per shiftPersonalised cleaning schedule with specialised equipment

67% Reduction

in production downtime

= $180,000+ saved monthly (average production value and cost of downtime)

Risk Mitigation

Protect Your Brand From Costly Recalls

A single contamination event can trigger a devastating product recall, erasing consumer trust and costing millions. The financial and reputational damage can threaten the very future of your business.

Emera is your first line of defence. We implement comprehensive contamination prevention protocols specifically designed for food manufacturing environments, safeguarding your products, your customers, and your bottom line.

- Proactive Contamination Prevention.

- Our detailed protocols for sanitation and cross-contamination control actively reduce the risk of pathogens.

- Safeguard Brand Reputation.

- Demonstrate your commitment to safety, protect customer trust, and secure your place in the market.

- Optional Microbial Testing.

- Add an extra layer of security with optional swab testing to verify the effectiveness of your sanitation program.

We understand the unique needs of food manufacturing facilities

Our specialised cleaning services are tailored to meet the rigorous standards required in food production environments.

Talk to an Expert Today“Emera Facility Services has been a reliable and professional partner for us. Their team understands the strict hygiene and compliance requirements in food manufacturing, and they’ve consistently delivered high standards across our site. From the beginning, they have demonstrated a commitment to excellence. Their expertise in maintaining a clean and compliant environment is invaluable. They adapt to our needs and ensure every corner of our facility meets industry standards. The team is knowledgeable and incredibly responsive. They support us promptly whenever needed. In short, Emera Facility Services provides top-notch service and peace of mind. We highly recommend them as a dependable and professional facility service provider.”

Frequently Asked Questions

Get answers to common questions about our specialised food manufacturing cleaning services.

Don't see your question answered here?

Contact UsRequest a Personalised Quote

Contact us today to discuss your facility's specific cleaning requirements.

Contact Information

Phone

1300 153 114

hello@emerafs.com.au

Office

16 Stelvio Close, Lynbrook, VIC 3975

10/440 Collins St, Melbourne VIC 3000

Our Service Areas

We provide specialised food manufacturing cleaning services throughout Melbourne and across Victoria.